Reliable Drive Systems for Grain Handling and Peak Season Demands

JOIN US AT: GEAPS Exchange - Feb. 21-24, 2025 | Kansas City, MO | Booth# 2926

Drive Technology That Delivers Power and Reliability

Agricultural products go through specialized processes of harvesting, storing, conveying, cleaning, drying, sorting, and handling to ensure that seasonal products reach the processing plants in perfect condition. SEW-EURODRIVE offers drive packages for bucket elevators, screw conveyors, discharge screw conveyors, chain conveyors, tube conveyors, belt conveyors, rotary gate valves, vacuum pumps, and drying systems. Choose from our wide selection heavy industry gear units combined with cutting-edge energy-efficient motors.

Parallel and Right-angle Gear Units

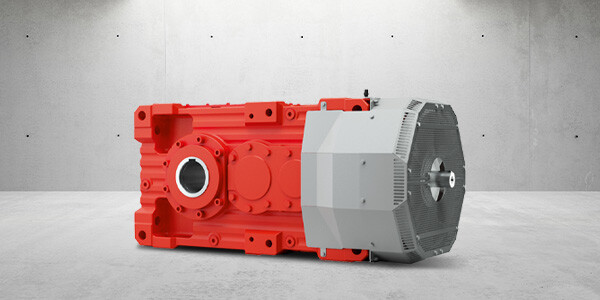

X.e Series gear units deliver reliable performance for grain handling equipment, including bucket elevators, conveyors, and rotary gates. With 23 sizes and modular flexibility, they manage high torque and harsh conditions reliably. For new systems or retrofits, our U.S.-assembled drive solutions offer durability, low maintenance, and long service life to keep grain operations running smoothly.

Screw Conveyor Drives

SEW‑EURODRIVE’s screw conveyor drive is built for grain handling and bulk material systems. With four-stage sealing, heavy-duty taper bearings, and thrust-load capacity, it protects against dust and contamination while delivering reliable performance. Tool-free shaft removal and flexible mounting make it ideal for high-load, high-duty environments in agriculture and feed processing.

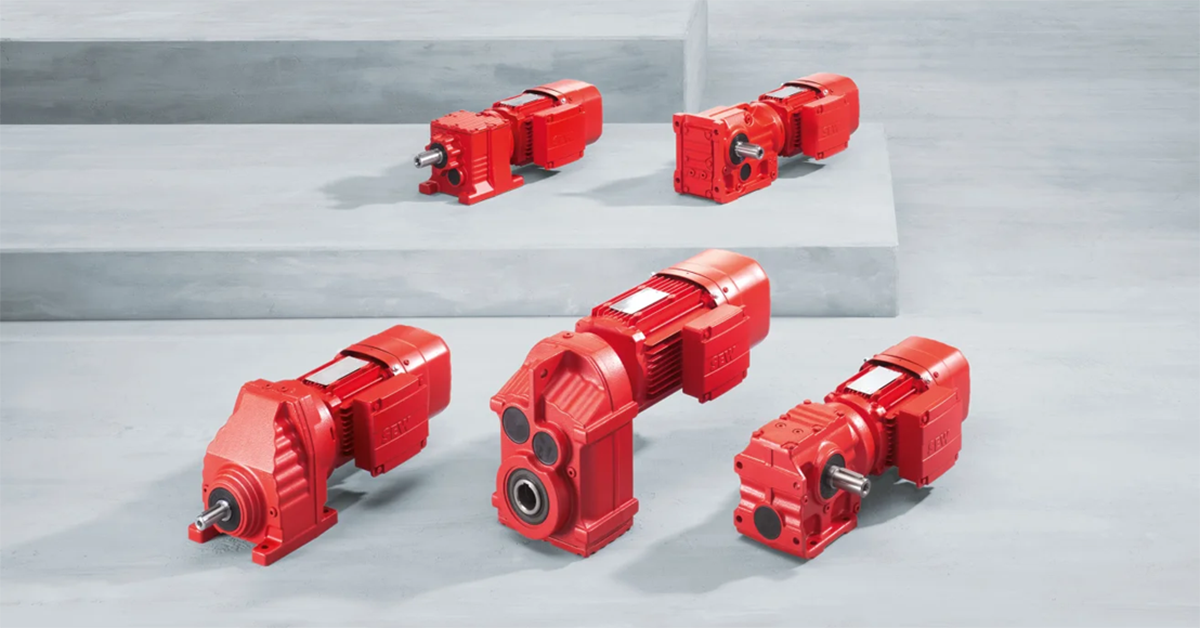

Standard Gearmotors and Gear Units

SEW‑EURODRIVE’s standard gearmotors combine high efficiency and rugged design for conveyors, mixers, and elevators in grain handling. With compact footprints, multiple mounting options, and a wide range of torque and speed combinations, they offer reliable, low-maintenance operation in dusty, demanding environments. Engineered for continuous duty and easy integration into bulk material systems.

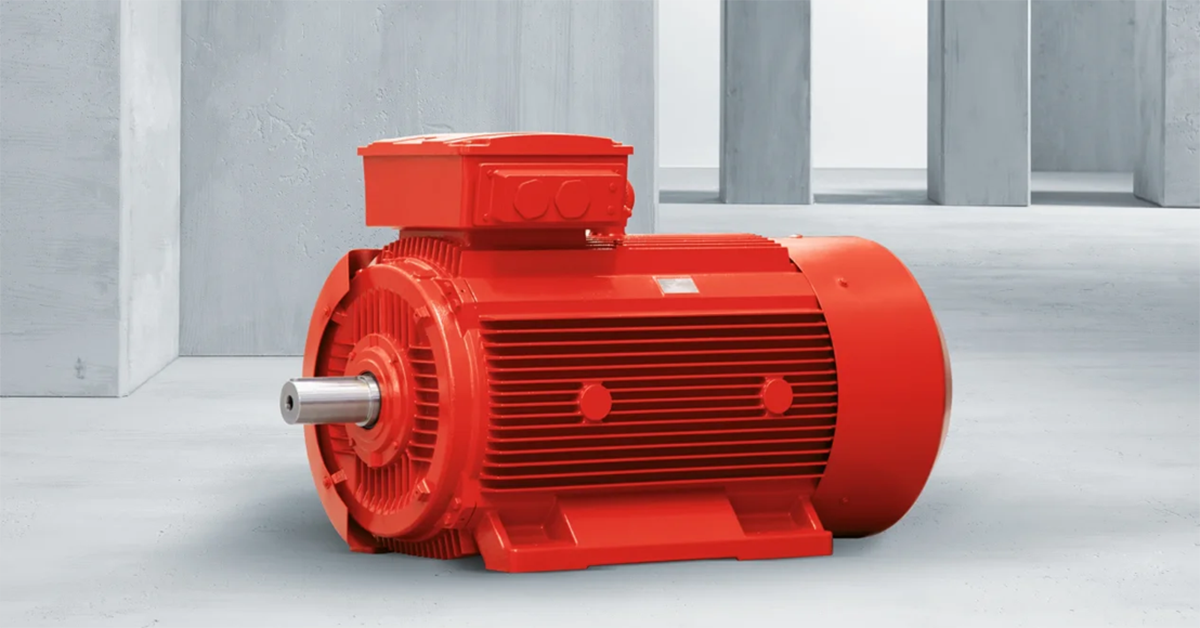

DRN.. series motors

SEW‑EURODRIVE’s DRN.. Series motors deliver the high torque and reliability needed for grain conveyors, bucket elevators, and high-inertia loads. The DRN355 offers up to 500 HP in a compact, rigid housing with global IE3 compliance and modular compatibility. Ideal for dusty, demanding environments, it pairs seamlessly with SEW-EURODRIVE gear units and cooling systems for heavy agricultural duty.

DRM../DR2M.. series torque motors

SEW‑EURODRIVE’s DRM../DR2M.. torque motors provide reliable stall torque for demanding grain handling equipment like rotary gates, valves, and positioning drives. Designed for continuous torque at standstill, these motors operate safely under high load, resist thermal overload, and integrate seamlessly with SEW-EURODRIVE’s modular system, making them ideal for bulk material control in elevators, conveyors, and silo systems.

Speaker: Kevin Blankenship

Solutions Engineer

Heavy Industrial Gear Products

SEW-EURODRIVE

GEAPS EXCHANGE 2026 SPEAKER EVENT

Innovation Station 1: Best Practices for Gear Reducer Lubrication

Monday, February 23, 2026 - 11:30 am to 12:15 pm

Join SEW-EURODRIVE's Kevin Blankenship as he explores how lubricant selection, oil type, inspection practices, and temperature all impact equipment health. Participants will have the opportunity to examine failed internal gear components and discuss real-world examples of lubrication-related failures. Come ready to ask questions, handle components, and leave with practical insights you can apply immediately in your facility.

Unable to attend the training session? Stop by Booth# 2926 to talk with one of our experts.

White Papers and Case Studies

Drive Modernization at a Cement Facility

Running an archaic chain-and-sprocket drive on four bucket elevators, a leading cement producer was struggling with inefficiency and downtime, costing thousands of dollars in lost production.

Sawmill Automation: Going Where Direct-Stop & Hydraulic Technologies “Cant”

Exploring the productivity and efficiency gains of outfitting a sawmill’s resaw line with VFDs, Ethernet and other automated electromechanical systems.

Reducing Waste in Wastewater Treatment

A municipal wastewater facility faced persistent maintenance issues with its screw-lift drive system, resulting in frequent breakdowns and continuous repair expenses.

Maximize Gearmotor Speed Range

Learn why to operate gearmotors above 60Hz. Through a common example, we will show you how to select the proper gearmotor that will significantly enhance performance.

Modular, Scalable Kinematics

Learn about functionally scaled robotics solutions consisting of individually customizable packages that fit nearly any automation robotics application.

Power and Energy Systems for the Evolving Factory

Explore industrial drives, power supplies, and energy solutions to reduce peak power usage and installation costs, and to promote overall system efficiency.

Modernized PET transport line achieves energy savings of up to 75%

Coca-Cola HBC Austria faced growing challenges with their aging transport line. High energy consumption and escalating CO2 emissions necessitated a pressing upgrade to meet sustainability targets and operational efficiencies.

Download Success Story:

Download Success Story:

Drive Modernization at a Cement Facility

Download White Paper:

Download White Paper:

Sawmill Automation: Going Where Direct-Stop and Hydraulic Technologies “Cant”

Download Success Story:

Download Success Story:

Reducing Waste in Wastewater Treatment

Download White Paper:

Download White Paper:

Maximize Gearmotor Speed Range

Download White Paper:

Download White Paper:

Modular, Scalable Kinematics.

Download White Paper:

Download White Paper:

Flexible Power and Energy Systems for the Evolving Factory

Download Case Study:

Download Case Study:

Modernized PET transport line achieves energy savings of up to 75%

Related Articles

Q&A: Thermal Performance and Gearbox Selection in Grain Handling Applications

Understanding how heat impacts gearbox life, oil performance, and uptime. In grain handling…

Optimizing Agricultural Operations with SEW-EURODRIVE

Reliable Drive Solutions for Peak Performance In the agriculture and grain handling industries,…