Efficient Baggage Handling & Airport Logistics Solutions

JOIN US AT: AAAE - May 3-5, 2026 | Los Angeles, CA | Booth# 428

High-Performance Solutions for Baggage Handling & Material Flow

SEW-EURODRIVE delivers complete, scalable solutions engineered for high-throughput airport applications such as baggage handling and complex material-flow logistics. Modular architectures simplify design, reduce commissioning time, and support flexible modernization. Operators rely on our proven uptime, quiet operation, and exact positioning. With decentralized drives, single-cable technology, high-efficiency motors, and predictive maintenance tools, SEW-EURODRIVE provides the performance, diagnostics, and global support needed to keep airport operations and logistics running smoothly.

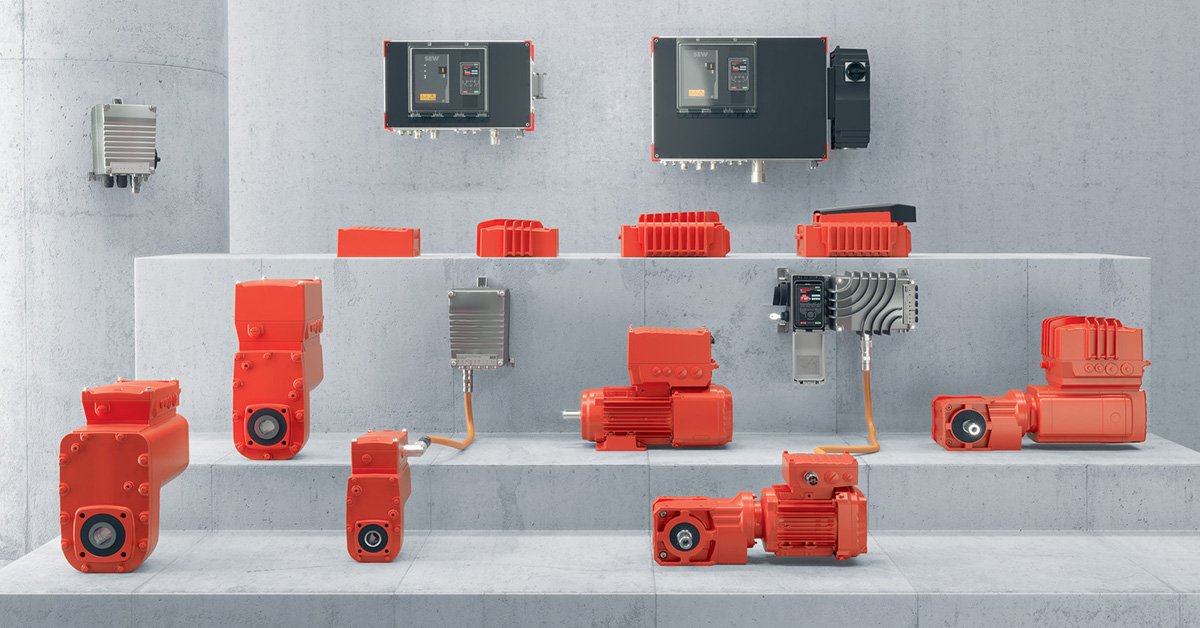

Decentralized Drive Solutions

The decentralized product family is a grouping of distributed drive and automation solutions engineered to simplify installation, reduce energy consumption, and maximize system uptime across high-throughput baggage handling and logistics environments.

- MOVIGEAR® combines motor, gear unit, and electronics in one efficient housing for energy-saving, fast conveyor setup.

- MOVIMOT® Performance / MOVIMOT® Advanced integrates a gearmotor and inverter to reduce wiring, save space, and deliver flexible torque control.

- MOVIPRO® Technology provides decentralized motion and control for positioning, coordination, and zone management.

Combined, these technologies streamline commissioning, reduce wiring by as much as 80%, and support modular, scalable system designs, perfect for building or modernizing baggage handling, material handling, and parcel logistics systems across today’s demanding airport facilities.

MOVILINK DDI® Single Cable Technology

Gearmotors with MOVILINK® DDI single cable technology use a true digital motor-interface, transmitting power, data, and diagnostics over one single cable, unlike analog feedback systems. This enables simplified plug-and-play setup, automatic drive/motor pairing, richer condition data, and faster commissioning, making it ideal for high-throughput logistics automation and conveyor systems.

Variable Frequency Drives (VFDs)

MOVITRAC® inverters deliver scalable, high-performance motor control with quick setup, robust overload capacity, and seamless integration into automation networks. Their modular design supports everything from simple conveyors to complex material-flow zones, providing reliable speed control, energy efficiency, and diagnostics for modern logistics and baggage handling systems.

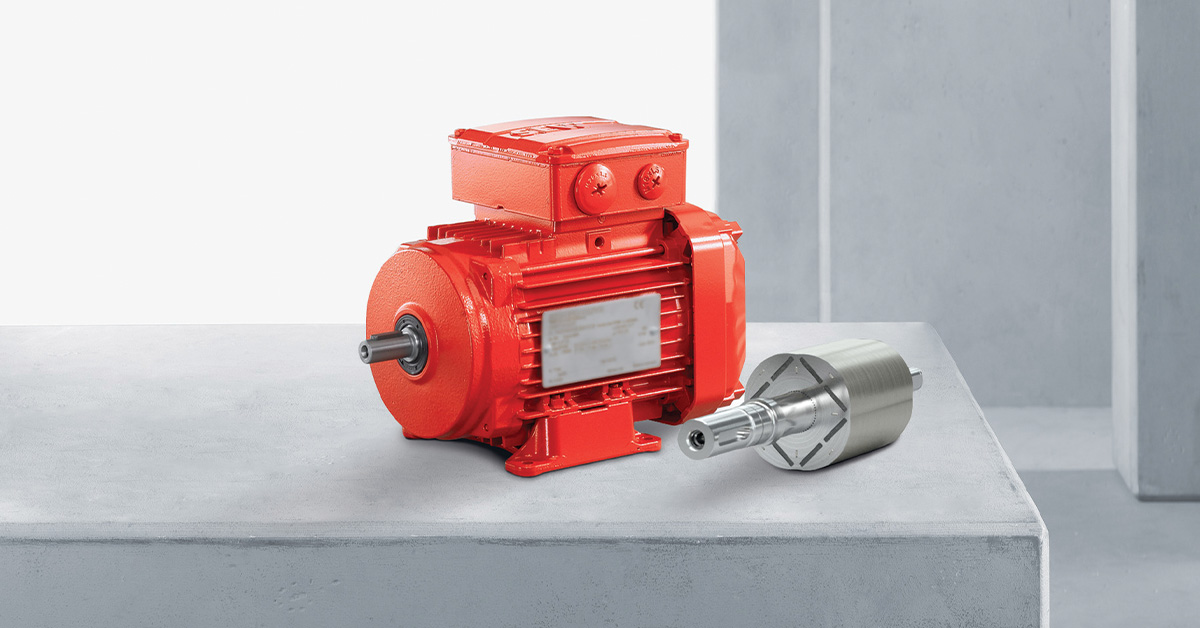

High-Efficiency Motors

DR2C IE5 synchronous motors deliver maximum energy efficiency for airport logistics. Certified to the highest IE class, they reduce power consumption through optimized speed control, smart time management, and right-sized load profiles—keeping baggage moving reliably while cutting operating costs.

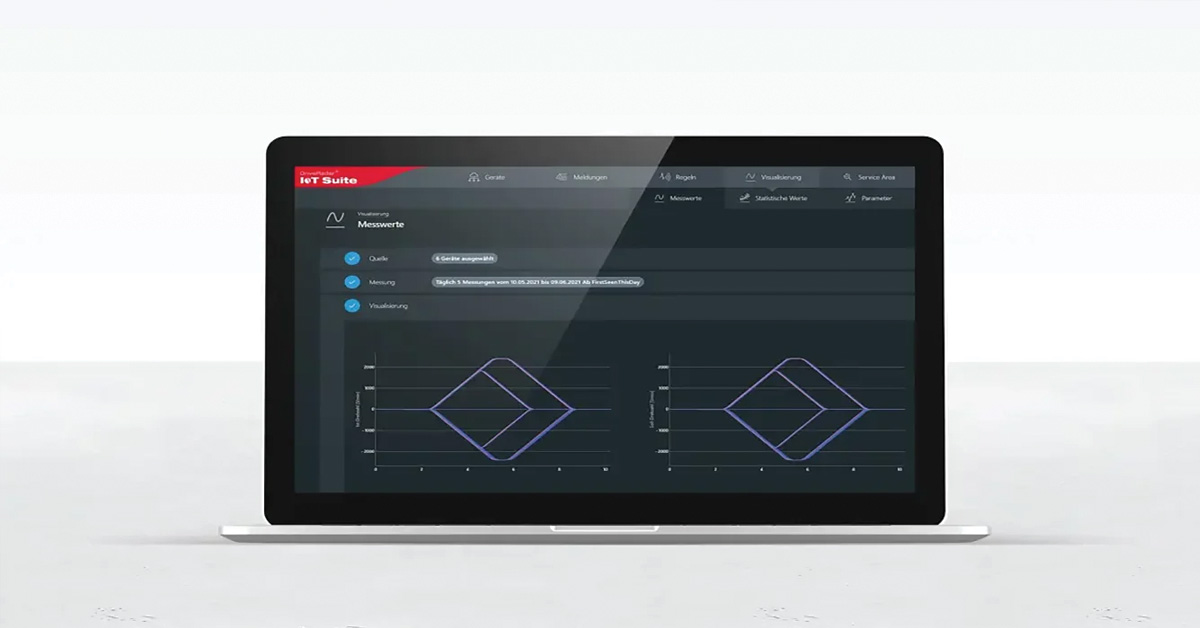

Predictive Maintenance

DriveRadar® IoT Suite brings powerful predictive maintenance to airport baggage handling. It detects faults early, reduces unplanned downtime, and enables data-driven service planning. With easy retrofit, no extra hardware, and cloud/edge monitoring, airports gain faster diagnostics, smarter maintenance, and higher long-term system reliability.

All-In-One Modular Automation Platform

MOVI-C® Modular Automation Platform is a fully unified automation and drive platform that combines motion control, power electronics, and engineering tools in one ecosystem. With seamless component integration, auto-parameterization, and advanced diagnostics, MOVI-C® simplifies design, speeds commissioning, and delivers precise, scalable performance for complex baggage handling and logistics automation.

White Papers and Case Studies

The first cross-belt sorter for Baggage Handling

To ensure luggage arrives reliably and quickly, you need technology that thinks ahead. With the help of SEW-EURODRIVE, Alstef Group has developed the first cross-belt sorter designed specifically for airports.

American Airlines Saves Nearly 40% in Energy Costs at LAX

LAX Terminal 4 baggage handling system upgrade met Title 24, power, space, and expansion needs for American Airlines and TSA.

Gatwick Airport reduces energy consumption with MOVIGEAR®

Gatwick Airport in London is experiencing constantly rising traffic. The existing luggage transportation systems were expanded in order to cope with this increase.

Cost Optimization at Munich Airport with Variant Management

Munich Airport implemented SEW-EURODRIVE's variant management in Terminal 1 to optimize the number of drive variants and reduce the spare parts inventory.

Maximize Gearmotor Speed Range

Learn why to operate gearmotors above 60Hz. Through a common example, we will show you how to select the proper gearmotor that will significantly enhance performance.

Power and Energy Systems for the Evolving Factory

Explore industrial drives, power supplies, and energy solutions to reduce peak power usage and installation costs, and to promote overall system efficiency.

Download Case Study:

Download Case Study:

American Airlines saves nearly 40% in energy costs at LAX

Download White Paper:

Download White Paper:

Maximize Gearmotor Speed Range

Download White Paper:

Download White Paper:

Flexible Power and Energy Systems for the Evolving Factory

Recent Articles

Q&A: Thermal Performance and Gearbox Selection in Grain Handling Applications

Understanding how heat impacts gearbox life, oil performance, and uptime. In grain handling…

Less heat. More options. A smarter stainless steel drive solution from SEW-EURODRIVE.

Why More OEMs Are Switching to Integral Stainless Steel Gearmotors In hygienic industries like…

SEW-EURODRIVE is Dropping the Ball… In the Best Way Possible

Behind the magic of the NYC New Year’s Eve Ball Drop Every year, as the final seconds tick away,…