Optimized Drive Solutions for Hygienic Applications

JOIN US AT: Cheese Expo - Apr. 15-16, 2025 | Milwaukee, WI | Booth #: 314

Drive Technology That Delivers Cleanability, Efficiency, and Uptime

In food and beverage production, hygiene, durability, and efficiency are not optional; they’re essential. Whether you're running aseptic filling systems for dairy and beverages, cutting equipment for meats and cheeses, or filleting machines for fish or poultry, SEW‑EURODRIVE delivers reliable drive solutions tailored for the job.

Our stainless steel gear units are engineered to perform in harsh washdown environments. With smooth, corrosion-resistant surfaces and robust IP69K protection, they are designed to meet stringent hygiene standards while ensuring long-term reliability and easy cleaning.

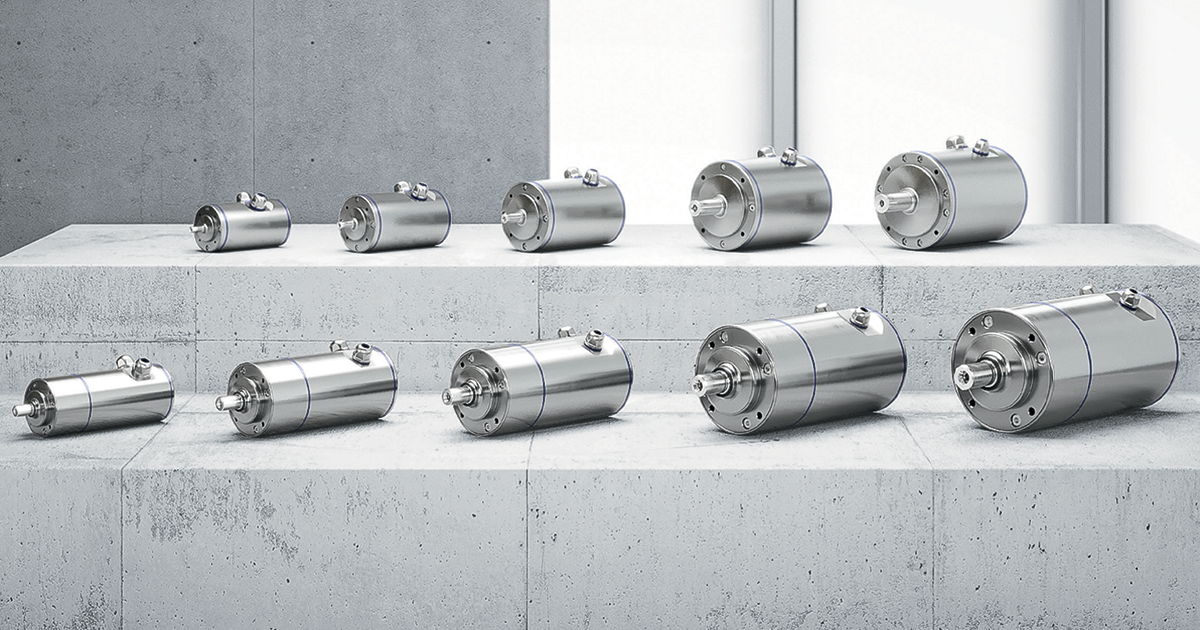

Stainless Steel Gear Units and Gearmotors

Due to the hygienic design and a surface that is resistant to acid and alkaline, these stainless steel gear units practically clean themselves. The three versions, helical gear, bevel gear, and SPIROPLAN® right-angle gear, allow use in a wide variety of applications.

NEW WES Series stainless steel gear units: Hygienic, compact, cool-running drive solution, even under continuous operation. Learn More

Stainless Steel Servomotors

Our stainless steel servomotors with a hygienic design meet the strict guidelines of EHEDG and the FDA. These compact units consisting of the synchronous servomotor and planetary gear unit are resistant against hot steam and corrosive cleaning agents.

Mobile transport and assistance systems

AGV's and logistics assistants for cleanrooms and areas with more stringent hygiene requirements. Our service portfolio extends from planning, vehicle design, and vehicle production through to startup and our installed base service.

Standard Gearmotor Protection Options

Our Food Industry Option Package (IOP) consists of specialized components designed to overcome the demands of chemical wash down environments. These components save you downtime and money by extending the life of both the gear unit and the motor.

Backed by decades of application expertise, our stainless steel portfolio is built around the key values that matter most: hygienic design, robust construction, and lasting flexibility.

White Papers and Case Studies

Modular, Scalable Kinematics

Learn about functionally scaled robotics solutions consisting of individually customizable packages that fit nearly any automation robotics application.

Power and Energy Systems for the Evolving Factory

Explore industrial drives, power supplies, and energy solutions to reduce peak power usage and installation costs, and to promote overall system efficiency.

Maximize Gearmotor Speed Range

Learn why to operate gearmotors above 60Hz. Through a common example, we will show you how to select the proper gearmotor that will significantly enhance performance.

Modernized PET transport line achieves energy savings of up to 75%

Coca-Cola HBC Austria faced growing challenges with their aging transport line. High energy consumption and escalating CO2 emissions necessitated a pressing upgrade to meet sustainability targets and operational efficiencies.

Sawmill Automation: Going Where Direct-Stop & Hydraulic Technologies “Cant”

Exploring the productivity and efficiency gains of outfitting a sawmill’s resaw line with VFDs, Ethernet and other automated electromechanical systems.

Download White Paper:

Download White Paper:

Modular, Scalable Kinematics.

Download White Paper:

Download White Paper:

Flexible Power and Energy Systems for the Evolving Factory

Download White Paper:

Download White Paper:

Maximize Gearmotor Speed Range

Download Case Study:

Download Case Study:

Modernized PET transport line achieves energy savings of up to 75%

Download White Paper:

Download White Paper:

Sawmill Automation: Going Where Direct-Stop and Hydraulic Technologies “Cant”

Related Articles

Less heat. More options. A smarter stainless steel drive solution from SEW-EURODRIVE.

Why More OEMs Are Switching to Integral Stainless Steel Gearmotors In hygienic industries like…

Clean. Compact. Less heat.

New from SEW-EURODRIVE: WES Series Stainless Steel Drives. Lyman, SC – SEW-EURODRIVE is proud to…

Food Production: How SEW-EURODRIVE Drives Excellence

Food Production: How SEW-EURODRIVE Drives Excellence The food industry faces unique and demanding…