Optimized Warehouse, Logistics, Material Handling, and Automation Solutions

JOIN US AT: MODEX - Apr. 13-16, 2025 | Atlanta, GA | Booth# B-16112 | FREE Registration with Code: INVITE14162

Efficient, Reliable, and Scalable Automation Solutions

SEW-EURODRIVE delivers integrated drive, control, and energy solutions engineered to maximize throughput across conveyors, sorting lines, Storage Retrieval Systems, shuttle technology, and high-density distribution environments. From digital motor interfaces and decentralized drive systems to advanced motion control, robotics software, and energy-optimized power platforms, our portfolio supports fast deployment, reduced downtime, and long-term operational resilience. Whether optimizing parcel flow, enhancing storage and retrieval performance, or enabling modular, future-ready layouts, SEW-EURODRIVE provides the technology backbone for today’s most demanding supply chain and intralogistics applications.

Gearmotors with MOVILINK DDI® Single Cable Technology

Gearmotors with MOVILINK® DDI single cable technology use a true digital motor-interface, transmitting power, data, and diagnostics over one single cable, unlike analog feedback systems. This enables simplified plug-and-play setup, automatic drive/motor pairing, richer condition data, and faster commissioning, making it ideal for high-throughput warehouse and logistics automation and conveyor systems.

Variable Frequency Drives (VFDs)

MOVITRAC® inverters deliver scalable, high-performance motor control with quick setup, robust overload capacity, and seamless integration into automation networks. Their modular design supports everything from simple conveyors to complex material-flow zones, providing reliable speed control, energy efficiency, and diagnostics for modern logistics and warehouse systems.

Extra-Low Voltage Drives with Integrated Electronics

MOVIMOT® performance ELV delivers high-efficiency motion on extra-low voltage for safer, decentralized conveyor and shuttle systems. Its integrated electronics, single-cable technology, and precise torque control enable compact layouts, reduced wiring, and reliable operation, ideal for energy-optimized, modular warehouse and logistics automation.

Servomotors

SEW-EURODRIVE offers a broad range of servomotor solutions for material handling, logistics, and warehousing, including low-inertia servomotors for high-speed motion, high-inertia servomotors for large moving masses, stainless steel servomotors for washdown areas, and integrated servo gearmotors for compact, high-torque applications. Designed for precise positioning, smooth acceleration, and reliable operation, these servos help OEMs optimize throughput, accuracy, and uptime in conveyors, palletizers, AS/RS, and gantry systems.

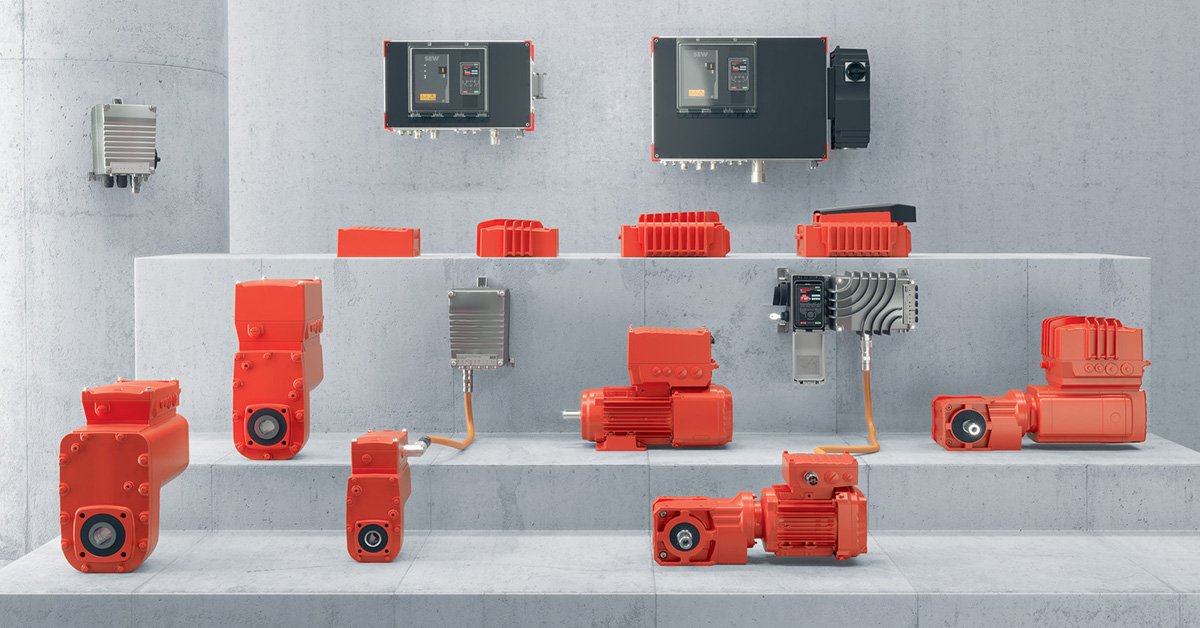

Decentralized Drive Solutions

The decentralized product family is a grouping of distributed drive and automation solutions engineered to simplify installation, reduce energy consumption, and maximize system uptime across high-throughput material-handling environments.

- MOVIGEAR® combines motor, gear unit, and electronics in one efficient housing for energy-saving, fast conveyor setup.

- MOVIMOT® Performance / MOVIMOT® Advanced integrates a gearmotor and inverter to reduce wiring, save space, and deliver flexible torque control.

- MOVIPRO® Technology provides decentralized motion and control for positioning, coordination, and zone management.

Together, these solutions minimize commissioning time, reduce wiring by up to 80%, and create modular, maintainable system architectures, ideal for dynamic warehouse, fulfillment, and distribution operations demanding speed, reliability, and energy efficiency.

All-In-One Modular Automation Platform

MOVI-C® Modular Automation Platform is a fully unified automation and drive platform that combines motion control, power electronics, and engineering tools in one ecosystem. With seamless component integration, auto-parameterization, and advanced diagnostics, MOVI-C® simplifies design, speeds commissioning, and delivers precise, scalable performance for complex warehouse and logistics automation.

Pre-engineered Software Modules

MOVIKIT® Software Modules offer pre-engineered function blocks for motion, positioning, robotics, and material-flow control. With standardized interfaces, auto-parameterization, and seamless integration into MOVI-C® Modular Automation Platform, they reduce programming time, simplify commissioning, and deliver consistent, high-performance automation for demanding warehouse and logistics systems.

Power and Energy Management

Power & Energy Solutions optimize high-throughput warehouses with regenerative power management, efficient gearmotors, and decentralized drives. Ideal for conveyors, sorting, Storage, and Retrieval Systems (SRS), and shuttle systems, these solutions cut energy use, boost uptime, and deliver scalable performance for fast-moving operations

AGVs and Track-Guided Systems

MAXOLUTION® AGVs and track-guided solutions deliver flexible, high-precision material transport for automated warehouses and production lines. With integrated navigation, scalable control, and seamless drive and safety technology, these systems improve flow, reduce manual handling, and enable modular, future-ready layouts tailored to dynamic intralogistics operations.

White Papers and Case Studies

Power and Energy Systems for the Evolving Factory

Explore industrial drives, power supplies, and energy solutions to reduce peak power usage and installation costs, and to promote overall system efficiency.

Modular, Scalable Kinematics

Learn about functionally scaled robotics solutions consisting of individually customizable packages that fit nearly any automation robotics application.

Maximize Gearmotor Speed Range

Learn why to operate gearmotors above 60Hz. Through a common example, we will show you how to select the proper gearmotor that will significantly enhance performance.

Modernized PET transport line achieves energy savings of up to 75%

Coca-Cola HBC Austria faced growing challenges with their aging transport line. High energy consumption and escalating CO2 emissions necessitated a pressing upgrade to meet sustainability targets and operational efficiencies.

Sawmill Automation: Going Where Direct-Stop & Hydraulic Technologies “Cant”

Exploring the productivity and efficiency gains of outfitting a sawmill’s resaw line with VFDs, Ethernet and other automated electromechanical systems.

Download White Paper:

Download White Paper:

Flexible Power and Energy Systems for the Evolving Factory

Download White Paper:

Download White Paper:

Modular, Scalable Kinematics.

Download White Paper:

Download White Paper:

Maximize Gearmotor Speed Range

Download Case Study:

Download Case Study:

Modernized PET transport line achieves energy savings of up to 75%

Download White Paper:

Download White Paper:

Sawmill Automation: Going Where Direct-Stop and Hydraulic Technologies “Cant”

Related Articles

Understanding Encoders

Enhancing Control Precision in Modern Automation In today’s automation environments, accurate speed…

Functional Safety in Motion Control

Beyond Emergency Stops In the world of industrial automation, it’s easy to think of safety as…

Food Production: How SEW-EURODRIVE Drives Excellence

Food Production: How SEW-EURODRIVE Drives Excellence The food industry faces unique and demanding…