Reverse Engineering for Precise Replacement

Precision Under Pressure: SEW-EURODRIVE Engineers Valuable Solution, Saving $70K a Day

When a critical gearbox failure halted a flour intake operation at a major food processing plant—costing $70,000 a day—SEW-EURODRIVE engineered and delivered a drop-in replacement in just seven weeks. By reverse-engineering the system and building a precision-fit gear unit, SEW-EURODRIVE restored full function with no structural rework or delays.

Challenge:

Catastrophic Gear Failure. No Direct Replacement. No Time to Re-engineer.

At a high-volume flour processing plant, a five-story bucket elevator responsible for ship unloading suffered catastrophic gearbox failure. The legacy OEM gear unit was no longer available.

With ships idling at the dock, the cost of downtime exceeded $70,000 per day. No off-the-shelf solution existed, and competitors quoted 16–20 week lead times, risking significant financial and logistical disruption.

The facility’s maintenance team needed a solution that could match the original footprint and shaft configuration without requiring rework—and they needed it fast.

|

“We were facing enormous downtime costs and no clear path forward. SEW‑EURODRIVE and their distributor partner delivered exactly what we needed—a drop-in solution without delays or rework.” |

/Case%20Studies/26-01_General%20Mills_9MD1515-0126/Images/SEW-Before_General-Mills_9MD1515_PXL_20240827_145005151.jpg)

/Case%20Studies/26-01_General%20Mills_9MD1515-0126/Images/SEW-After_General-Mills_9MD1515-1.jpg?width=2000&height=1500&name=SEW-After_General-Mills_9MD1515-1.jpg)

Solution:

A True Drop-In Gear Unit Replacement—Delivered in Seven Weeks

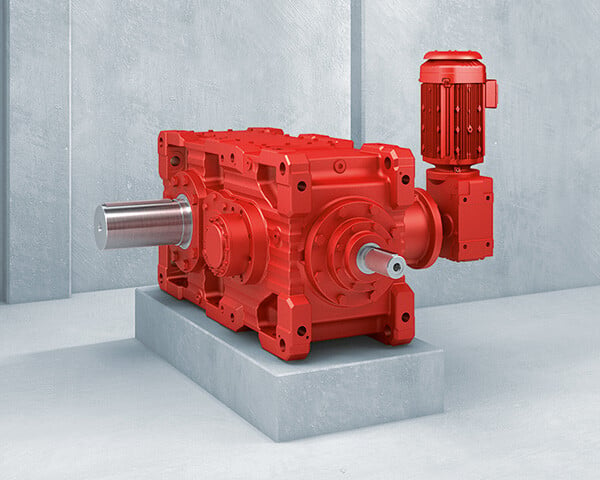

SEW-EURODRIVE designed, built, and delivered a XSFS160e helical-bevel gear unit with a 20:1 ratio and a precision transition baseplate to match the existing bolt pattern and shaft centerline. A C-face motor with centering dowels allowed quick, alignment-free installation. The system retained the original coupling and motor orientation, reducing complexity and accelerating the timeline.

SEW-EURODRIVE’s internal expedite team coordinated engineering, assembly, and logistics at its U.S.-based Heavy Industry Gearing (HIG) facility in Wellford, SC. The complete drive package was delivered to spec and in sync with the plant’s crane and rigging schedule. The bucket elevator was operational within seven weeks, with no structural changes required.

|

“The ability to reuse the existing footprint and shaft location was critical. That meant no redesign, no custom foundation work—just drop it in and go.” |

SEW-EURODRIVE Advantage:

Delivering What No Other Supplier Could

SEW-EURODRIVE was the only supplier with the engineering agility, U.S. stock and assembly capability, and retrofit experience to meet the challenge. SEW-EURODRIVE delivered what others couldn’t, including:

- Customizing a mechanical fit without rework

- Building and testing in the U.S. to eliminate import delays

- Aligning all logistics for seamless installation

- Delivering in seven weeks with full system integrity

Application Summary:

Application Areas:

- Off-load bucket elevator

SEW-EURODRIVE Product(s):

- Gear Unit

X.e Series

X3FS160e/HU/B

Ratio 39.72:1

Operating TQ: 202,600

Foot Mount

Splash Lube

NEMA C / 444/445 adapter

- Motor

NEMA C / 444/445 adapter

148HP

1780RPM

460V

PTC Thermistor

CL1 Div2 Grps B, C, D T3

CUSTOMER:

Flour Processing Plant

INDUSTRY:

APPLICATION:

PREVIOUS TECHNOLOGY:

Legacy Gear Unit

SOLUTION:

X.e Series helical-bevel gear unit

X3FS160e/HU/B

Bucket Elevator Drive

JOIN OUR NEWSLETTER:

Image Gallery:

About SEW-EURODRIVE

Founded in 1931 in Bruchsal, Germany, SEW-EURODRIVE is a global leader in Industrial Automation, with operations in over 50 countries, 17 manufacturing plants, 92 assembly facilities, and more than 21,000 employees. The company holds over 1,000 patents, continuously driving technological advancements in gearmotors, frequency inverters, servo drives, and Industry 4.0 solutions.

SEW-EURODRIVE provides engineered solutions in countless industries, including automotive, food & beverage, pharmaceuticals, mining, steel, logistics, energy, and more, providing customized automation solutions that enhance efficiency, productivity, and sustainability. Despite its global reach, SEW-EURODRIVE remains family-owned, ensuring long-term vision, strong values, and a commitment to excellence.

SEW-EURODRIVE. Driving the World™

SEW-EURODRIVE, Inc.

220 Finch Road

Wellford, SC 29385

(P): (864) 439-7537

cslyman@seweurodrive.com

www.seweurodrive.com

/Case%20Studies/26-01_General%20Mills_9MD1515-0126/Images/SEW-After_General-Mills_9MD1515-1.jpg)

/Case%20Studies/26-01_General%20Mills_9MD1515-0126/Images/SEW-After_General-Mills_9MD1515-2.jpg)